Deionised Water vs Reverse Osmosis: Which Is Better for Your Business?

Many businesses that rely on high-purity water encounter two widely used terms: Deionised (DI) water and Reverse Osmosis (RO) water. Both are essential technologies in commercial and industrial water treatment, and understanding the differences between them supports better decision-making, improved compliance, and more efficient operations.

Knowing how each method works and where it delivers the most value can help ensure the right investment in long-term water quality. Industries such as manufacturing, food processing, laboratories, and pharmaceuticals benefit from selecting the most appropriate purification system based on their specific performance and regulatory needs.

What Is Deionised Water and How Is It Used?

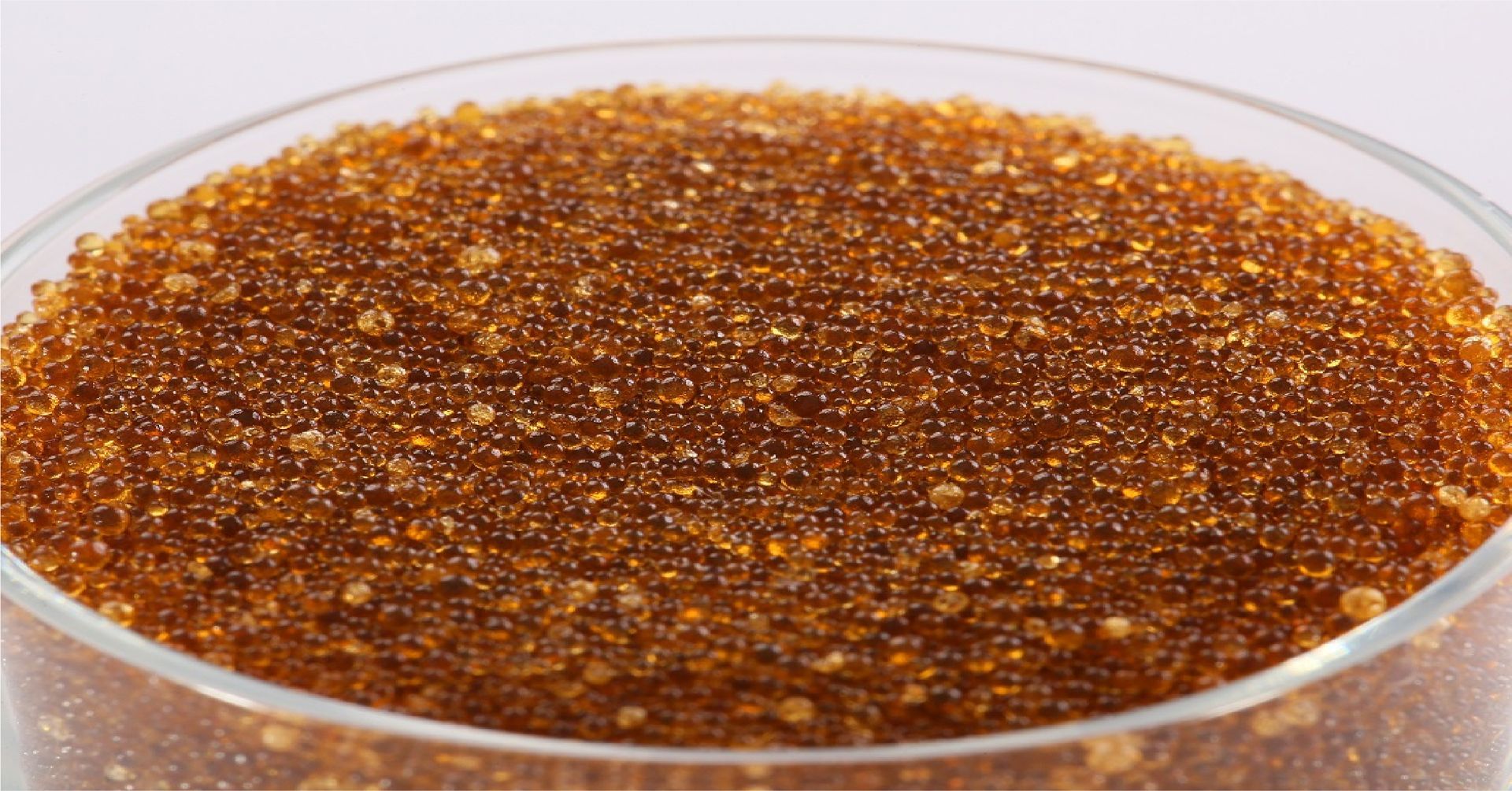

How Deionised Water Is Produced

Deionised water is created by removing electrically charged particles (ions) from the water using an ion exchange process. This method targets dissolved salts, minerals, and other inorganic substances, resulting in water with low electrical conductivity and high ionic purity.

The process uses a combination of cation and anion exchange resins, which replace unwanted ions in the water (such as calcium, magnesium, chloride, and nitrate) with hydrogen and hydroxide ions. These ions then combine to form pure water molecules.

Common Purity Levels

Deionised water typically achieves resistivity values between 0.1 to 18.2 megohm-cm, depending on the system design and the number of purification stages. This process effectively removes inorganic ions but does not filter out bacteria, viruses, or organic molecules. Under optimal conditions deionised water can reach resistivity values up to 18.2 MΩ·cm, however this is typically in laboratory settings with multi-stage treatment.

Typical Industrial Applications

Deionised water is used where the presence of minerals could disrupt processes or damage equipment. Common uses include:

- Electronics manufacturing and circuit board cleaning

- Laboratory testing and equipment sterilisation

- Battery production and maintenance

- Automotive and glass rinsing

- Cosmetic and chemical formulations

Deionised water supports precision, consistency, and equipment longevity in industries that require minimal mineral interference.

What Is Reverse Osmosis Water and How Does It Work?

How Reverse Osmosis Works

Reverse osmosis is a water purification process that uses a semipermeable membrane to remove a wide range of contaminants. Water is forced through this membrane under pressure, allowing only water molecules to pass while blocking ions, dissolved salts, bacteria, and many organic substances.

A reverse osmosis system typically includes multiple stages of filtration, such as sediment and carbon filters, before water reaches the membrane. These pre-filtration stages help extend membrane life and improve overall system performance.

Water Purity Levels Achieved

Reverse osmosis water achieves high levels of purity, typically removing up to 99% of dissolved solids, including both inorganic and organic contaminants. The resulting water is suitable for applications where broad-spectrum contaminant removal is required.

Typical Industrial Applications

Reverse osmosis systems are commonly used in settings that demand consistent, high-purity water across a wider range of contaminants. Typical applications include:

- Food and beverage manufacturing

- Pharmaceutical production

- Boiler feedwater treatment

- Dialysis and medical device cleaning

- Commercial kitchens and beverage dispensers

Reverse osmosis water supports hygiene, product quality, and compliance in industries where safety and purity standards are tightly regulated.

Key Differences Between Deionised and Reverse Osmosis Water

Understanding the distinctions between deionised and reverse osmosis water can support better system design, maintenance planning, and application suitability.

Comparison Guide

*Operating costs vary depending on system size and water demand. DI systems may have lower energy use but incur recurring resin replacement or regeneration costs, while RO systems require more energy but lower chemical handling.

Each system has specific strengths depending on the contaminants present, required water quality, and operational demands. Selecting the right approach helps ensure water reliability and system efficiency.

Which One Is Better for Your Business?

When to Choose Deionised Water

Deionised water is a strong choice for applications that require high ionic purity without concern for organic contaminants. It is particularly useful in environments where dissolved salts and minerals must be eliminated to prevent spotting, scale build-up, or interference with sensitive processes.

Suitable scenarios for deionised water include:

- Rinsing components in electronics or automotive manufacturing

- Filling batteries in transport or emergency power systems

- Laboratory applications where mineral content could affect testing accuracy

- Chemical mixing or formulation where consistent ionic composition is critical

Deionised systems are often cost-effective for facilities that need high-purity water in moderate volumes and where organics, bacteria, or particulate matter are not a major concern. In some cases, additional filtration may be recommended to achieve the desired outcome.

When to Choose Reverse Osmosis Water

Reverse osmosis water is preferred when there is a need to remove a broader spectrum of impurities, including both inorganic and organic substances. It is especially important in industries where water quality directly affects product safety, hygiene, or regulatory compliance.

Ideal use cases for reverse osmosis water include:

- Food and beverage production requiring consistent taste, clarity, and safety

- Pharmaceutical manufacturing where sterility and purity are essential

- Boiler feedwater treatment to reduce scaling and corrosion

- Medical device cleaning where microbial and chemical residues must be minimised

Although reverse osmosis systems typically involve a higher initial investment and operating cost, they offer excellent reliability and flexibility in demanding environments with strict water quality standards.

Comparison Guide

Can You Combine Deionised Water and Reverse Osmosis Systems?

Combining reverse osmosis and deionisation is a common and effective strategy for achieving ultra-pure water in high-demand environments. This hybrid approach uses a reverse osmosis system as a pre-treatment stage, followed by a deionisation system to further polish the water to required purity levels.

Benefits of Combining RO and DI Systems

- Extended Resin Life: Reverse osmosis removes the majority of dissolved solids before water reaches the ion exchange resins. This significantly reduces the workload on the resins, extending their lifespan and reducing replacement frequency.

- Improved Cost Efficiency: Using RO as a first stage lowers the operating cost of the DI system by reducing resin consumption.

- Higher Water Purity: This two-stage setup delivers consistently high-quality water suitable for applications with strict purity standards, including those involving sensitive manufacturing or laboratory processes.

Industries That Benefit from Combined Systems

- Biotechnology and life sciences

- Pharmaceutical production

- Laboratories and testing facilities

- Microelectronics and semiconductor manufacturing

These industries often rely on water that is free from both ionic and organic contaminants, making a dual-stage RO/DI system a practical and effective solution.

Let AP Water Help You Find the Right Solution

Selecting the right water purification system requires a clear understanding of your water source, industry standards, and operational requirements. AP Water specialises in designing and supplying high-performance commercial and industrial water systems that deliver consistent, reliable results.

With more than 25 years of experience, our team provides:

- On-site assessments to evaluate source water and process needs

- Systems tailored to your specific applications

- Locally assembled RO and DI systems for faster turnaround and ongoing support

- Technical advice and maintenance services to keep your system running efficiently

To make the most of your water treatment investment, partner with a team that understands the technical and operational demands of your industry. Whether your priority is ionic purity, broad contaminant removal, or a combination of both, AP Water delivers tailored systems that perform.

Contact us online today or call 03 9534 3674 to speak with an expert about the best solution for your business.

Deionised Vs Reverse Osmosis FAQ

What is deionised water used for in industrial applications?

Deionised water is commonly used in industries where dissolved minerals must be eliminated to avoid interference with processes or equipment. Typical applications include electronics manufacturing, laboratory testing, battery maintenance, and glass rinsing. Its high ionic purity makes it suitable for sensitive environments.

How does reverse osmosis work in a commercial water system?

Reverse osmosis works by forcing water through a semipermeable membrane that removes a wide range of contaminants, including salts, particles, and organics. In a commercial water system, this process is supported by pre-filtration stages such as carbon and sediment filters, ensuring consistent and reliable water purity.

What are the key differences between deionised water vs reverse osmosis water?

Deionised water removes only ions through an ion exchange process, while reverse osmosis removes a broader range of contaminants including ions, organic compounds, and microbes. Deionisation is often used in laboratories and electronics, while reverse osmosis is preferred for food production, pharmaceuticals, and boiler systems.

Can a reverse osmosis system and a deionisation system be used together?

Yes. Many commercial and industrial facilities use a reverse osmosis system as a pre-treatment stage before deionisation. This approach improves overall water purity and extends the life of the deionisation resin, reducing long-term maintenance costs.

Which types of purified water are best for manufacturing or medical use?

For manufacturing and medical applications, reverse osmosis water is often the preferred choice due to its ability to remove both inorganic and organic contaminants. In some cases, combining RO and DI systems delivers the high water purity levels required for compliance and performance.

How do water purity levels compare between deionised and reverse osmosis water?

Both methods achieve high water purity levels, but in different ways. Deionised water has very low ionic content but may still contain organic or microbial contaminants. Reverse osmosis water has a broader purity profile, removing up to 99% of dissolved solids, organics, and particles.